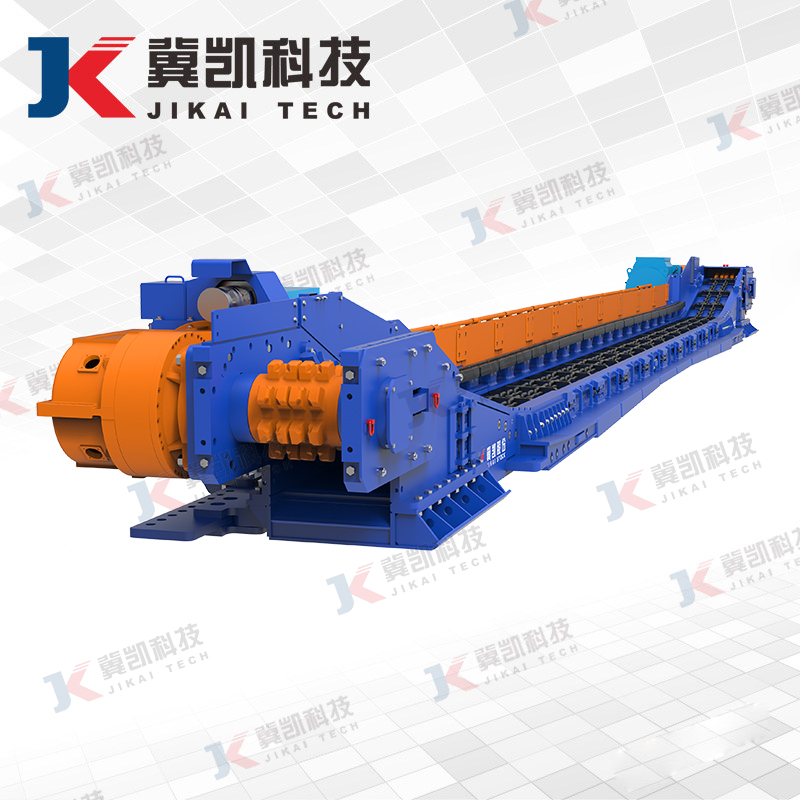

Product Introduction

The inblock casting scraper conveyor is the fifth technological revolution. It has been rated as "international leading level" by experts in the coal industry (2 invention patents, 5 utility model patents and 5 provincial and municipal awards). It has been awarded as a national key new product by the Ministry of science and technology, the Ministry of environmental protection and the development and Reform Commission.

In 2018, the inblock casting scraper conveyor won the first prize of science and technology of China's coal industry.

Our company presided over the preparation of China's first energy industry standard for inblock casting scraper conveyor (Nb / T 10384-2019), which was officially promulgated and implemented on July 1, 2020.

The products have been widely used in major domestic coal mining groups such as Datong Coal Group, Huainan Mining, Pingmei Group, Yitai Group, Yongmei Group, and are exported to Russia, Iran, Poland and other major coal-producing countries in the world.

Technical Features

As thepioneer in the inblock casting technology industry, it is the first choice of scraper conveyor for fully mechanized mining face;

High strength, high wear resistance, corrosion resistance and long service life, which is twice longer than that of traditional scraper conveyor;

Corrugated design can save energy and reduce consumption, and the operating power of the whole machine is 10% ~ 30% lower than that of the traditional scraper conveyor;

Technical features of intelligent 3D molding inblock casting scraper conveyor

The intelligent 3D molding inblock casting scraper conveyor is equipped with an industry-leading intelligent control system, which is suitable for a full range of scraper conveyor products. The centralized control center controls and monitors the scraper conveyor, transfer machine, crusher, belt conveyor, self moving device, etc. Ten functions can be realized:

1. Sequential start and stop, emergency stop and lock;

2. Smart start;

3. Automatic chain tension relaxation and chain breaking protection;

4. Coal quantity monitoring system;

5. Intelligent speed regulation;

6. Power unit operation status monitoring;

7. Power unit operating status health diagnosis, fault early warning protection;

8. Interlocking and centralized control between the chute and the equipment of the working face;

9. Support the remote control of the third-party host computer;

10. Automatic data transmission in the central control center

Parameters

| Product Series | Installed Power(kW) | Conveying Capacity(t/h) | AFC Pan Inside width(mm) | Design Maximum Length(m) | Scraper Chain Type | Line Pan Structure |

| 630 Series | 2×(110~200) | 250~450 | 590(580) | 100,150 | Single chain / medium double chain | Inblock Casting |

| 730 Series | 2×(132~250) | 450~700 | 690(680) | 100,150,200 | Single chain / medium double chain | Inblock Casting |

| 764 Series | 2×(200~400) | 700~1000 | 724 | 150,200 | Medium double chain | Inblock Casting |

| 800 Series | 2×(315~525) | 1200~1500 | 800 | 150~250 | Medium double chain | Inblock Casting |

| 830 Series | 2×(250~400) | 1200 | 780 | 150,200 | Medium double chain | Inblock Casting |

| 900 Series | 2×(400~855) | 1500~2000 | 900 | 150~300 | Medium double chain | Inblock Casting |

| 1000 Series | 2×525~3×1000 | 1800~3000 | 1000 | 150~300 | Medium double chain | Inblock Casting |

| 1200 Series | 2×(700~1200) | 2500~3000 | 1200 | 250~300 | Medium double chain | Inblock Casting |

| 1250 Series | 3×(855~1500) | 3000~3500 | 1250 | 300~400 | Medium double chain | Inblock Casting |

| 1400 Series | 3×(1200~1600) | 4000 | 1400 | 400 | Medium double chain | Inblock Casting |