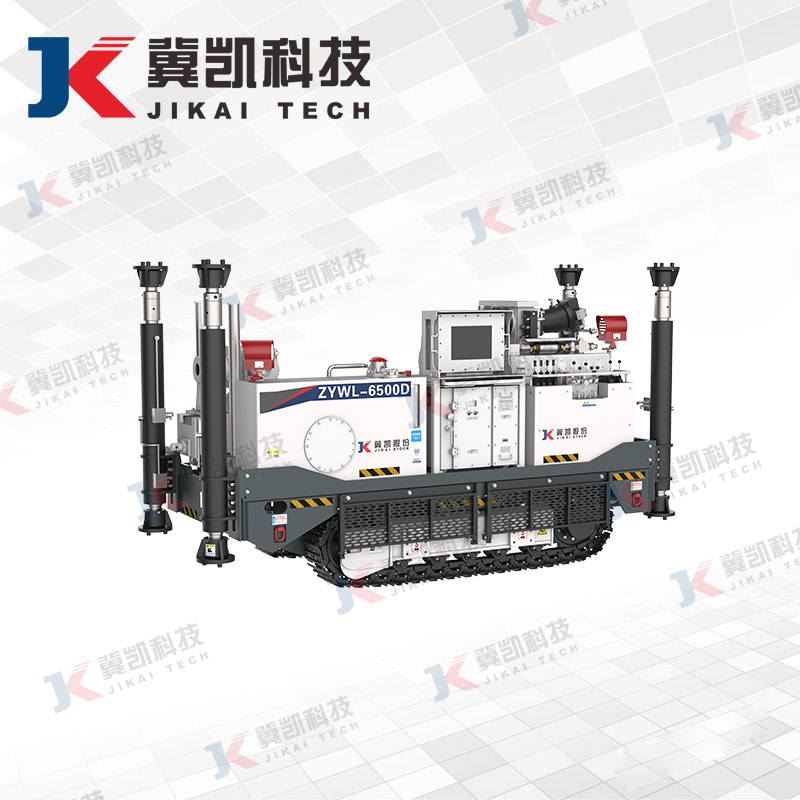

CMS1-6500/75D Coal mine deep hole directional drilling jumbo adopts a split structure and is suitable for motor directional drilling and grouting at the bottom of the bore rotary drilling, and other construction technology, can be used in the coal mine gas drainage drilling construction, can also be used for downhole drilling drainage, geological structure and coal seam thickness detection, coal seam affusion, roof and floor grouting etc. All kinds of high precision of the directional drilling construction. Supporting equipment: directional drill + screw motor + measuring pipe + magnetic drill pipe + cable drill pipe + explosion-proof computer.

Product Features

Stable, convenient and efficient

The drilling jumbo adopts horizontal layout, with upper and lower jacking support cylinders arranged at four corners, and front jacking cylinder arranged at the front of the guide rail to achieve fast support drilling and steady drilling.

Track presets, real-time display

Multi-directional branch drilling, preset drilling trajectory; high-precision measurement while drilling system, real-time display of main parameters such as drilling inclination, azimuth, tool face angle, and precise control of drilling direction.

High power and high drilling efficiency

The stepless variable motor drives rotary drilling, and the high-torque bottom-hole motor directional drilling has high drilling efficiency. Energy-saving and high-efficiency load-sensing system and pilot proportional control system can precisely control the feed speed and rotation speed.

Split structure, flexible and convenient

The whole machine is composed of a main car and a pump car, and the two cars walk independently, and the drilling field is flexible and convenient.

Wide range of applications

It is suitable for gas drainage drilling, exploration and drainage drilling, geological exploration drilling hole, coal seam water injection drilling hole and various engineering drilling holes in this coal seam, high position and floor penetration layer.

Parameters

| Drilling Jumbo |

CMS1-6500/75D | ||

| Total power(kw) | 75 | ||

| Overall size(mm) | 3700*1450*1900 | ||

| Swing motor maximum torque(N.m) | 6500 | ||

| Bottom hole motor maximum torque(N.m) | 730 | ||

| Max. braking torque(kN) | 1000 | ||

| Max. pulling force/feeding force(kN) | 230 | ||

| Drilling inclination(°) | -10-+20 | ||

| Horizontal Drilling height(mm) | 1450-1900 | ||

| Drilling Depth(m) | 600 | ||

| Pump car | Total power(kw) | 75 | |

| Overall size(mm) | 2600*1000*1500 | ||

| Rated Flow(L/min) | 260 | ||

| Max. Pressure(Mpa) | 10 | ||

| Measurement-while-drilling measuring device | Item | Measuring range(°) | Allowable error |

| Inclination | -90~+90 | ±0.15 | |

| Direction angle | 0-360 | ±1.2 | |

| Roll angle | 0-360 | ±1.2 | |

| Drill field size (in the direction of opening) | Length | Width | Height |

| ≧8000 | ≧5000 | ≧2500 | |

Measurement while drilling system

Product Description

YZG18.5 mine electromagnetic wave while drilling trajectory measuring instrument is composed of YZG18.5-Z mine electromagnetic wave while drilling trajectory measuring instrument host and YZG18.5-T mine electromagnetic wave while drilling trajectory measuring instrument probe pipe. Directional near-horizontal drilling, the directional sub-section of the probe collects hole bottom data, electromagnetic waves wirelessly transmit signals, real-time display of drilling trajectory data, and effectively guide construction personnel to adjust the direction of the drilling trajectory.

Parameters

| Specifications and Models | YZG18.5 |

| Inclination | Range ±90° Accuracy ±0.2° |

| Direction angle | Range 0-360° Accuracy ±2° |

| Roll angle | Range 0-360° Accuracy ±2° |

Transmission mode |

Remote Control |

| Probe diameter | 73mm |

| Probe length | 2.7m |

| Protection class | IP65 |

| Battery operating time | ≧60h |